คำอธิบาย

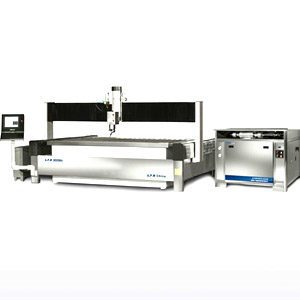

XF-2513 ultra-high pressure

Characteristic

Designed according to the standards of products exported to the United States, the internal

structure is welded with a frame type bridge structure, and the entire machine is tempered to

eliminate stress. Cantilevered structure, capable of cutting any complex planar curve. Users

can load and unload materials from three aspects. 1. Adopting high-quality high-speed turbochargers, key components imported from the

United States, with stable pressure, small fluctuations, and high cutting efficiency. Compared

to similar products in the market, the cutting efficiency is improved by more than 30%. 2. The high pressure generator can start and stop the oil pump, high pressure and air cooler

independently of the control cabinet, and the opening and closing time of the hydraulic

reversing valve is controlled microscopically at the millisecond level with a single chip

microprocessor, which reduces the dwell time of the reversing dead point, improves the

hydraulic Energy conversion efficiency, and reduces the heat generation of the oil pump. 3. Cantilever type bed structure, capable of loading on three sides, with timely stress

removal for the entire machine. Taiwan’s high-precision linear guide screw has high

transmission accuracy, and the Z-direction structure is made of aluminum alloy material, with

light weight. 4. The control system adopts the advanced domestic Huaxing control system. 5. Advantages of three-axis cutting head

-Steel structure base; -Servo drive; -Integrated cutting head; -Fully automatic control system; -Capable of achieving seamless

Performance Description

1. Cantilever series CNC cutting platform

1.1 Cantilever type machine tool structure

Designed and produced according to the standards of products exported to the United States, the internal

structure is welded with a frame type bridge structure, and the entire machine is tempered to eliminate

stress. Cantilevered structure, capable of cutting any complex planar curve. Users can load and unload

parts from three directions, overcoming the narrow loading and unloading space of gantry machine tools

Steel structure base: The cantilever of the invisible variable machine tool is customized by a Japanese

wholly-owned steel pipe factory, with a seamless 16 manganese 10mm thick rectangular tube. Arm structure: capable of cutting any complex planar curve. Servo feed system: equipped with Weizhi servo motor, imported high-quality ball screw, linear guide rail

(internationally renowned brand Taiwan TBI)

Capable of achieving seamless motion: ensuring smooth

operation, the bed direction adopts a 40mm diameter (50mm

for SQ40 machine tool) lead screw to ensure smooth

transmission of the entire machine tool. -Workbench size: 2520mm1320m

-X-axis stroke: 2500mm

-Y-axis stroke: 1300mm

-Z-axis stroke: 200mm

1.2 High quality stainless steel dust prevention device:

Adopting a fully stainless steel structure, it effectively protects the mechanical transmission

structure of the X, Y, and Z axes in all directions. The cutting head is equipped with a cup

shaped dust cover to prevent water and sand splashing during cutting. The PVC skeleton is

sturdy and durable, and the PTFE slider is wear-resistant but not

The damaged guide rail and stainless steel outer protection frame have improved the overall

service life and protection effect. The overall process structure is reasonable, waterproof, oil

resistant, and wear-resistant, with a long service life. 1.3 Water tank: -Durable and sturdy, the inner liner is made of 5mm thick carbon steel plate, and the panel is

made of stainless steel plate. -Adopting a separate design between the bed and the cutting platform, the cutting process is

not affected by vibration and improves cutting accuracy. 1.4. Integrated cutting head and ultra-high pressure pipeline:

-Pneumatic ultra-high pressure water switch

-Integrated cutting head

-7m of ultra-high pressure pipe from generator to machine tool -Gem nozzle

-Abrasive sand tube

-Adopting a unique process design, without adjustment, ensuring that the gemstone water

nozzle is absolutely concentric with the sand pipe, resulting in higher cutting efficiency. 1.5 Transmission system

Adopting Taiwan TBI high-quality seamless ball screw and Taiwan TBI linear rolling guide rail, ensuring transmission accuracy, durability, and high quality. 1.6 Protection System

-Dual protection function of over travel automatic limit and soft limit. -Unique protection design: New stainless steel labyrinth protection and Z-direction fully

enclosed water knife professional design, ensuring that the splashed sand and water during

the cutting process cannot corrode the screw and guide rail. 1.7 Lubrication system

-Adopting an automatic centralized lubrication system, the lubricating oil automatically

reaches every lubrication point in the transmission system on time, making the machine tool

work more stable, reliable, and easy to maintain

1.8 Main technical parameters

2. Abrasive cutting system

The abrasive cutting system consists of an integrated abrasive cutting head, high-pressure water

switch, sand control valve, sand hopper, etc. 2.1 Integrated abrasive cutting head

Xufeng’s self-developed integrated abrasive cutting head is one of the most efficient abrasive cutting

heads in the world. -Easy replacement of vulnerable parts

2.2 High pressure water switch

-Pneumatic valve can achieve instant opening and instant (delayed) closing of high-pressure water

-Automatic control of high-pressure water through CNC auxiliary function

2.3 Sand control system

-Self suction sand supply method

-Manual replenishment of sand material (with the automatic sand feeding system, the automatic

sand feeding function can be achieved)

2.4 Sand control valve

-Self suction sand supply method

-Pneumatic valve to overcome sand blockage and breakage caused by magnetic properties of

electromagnetic valves

-Manually adjustable sand flow rate

-Automatic control of abrasive supply through CNC auxiliary function

2.5 Sand hopper

-Side hung sand cup

-There is a window on the side for observing abrasive consumption, which is used to remind

operators when they need to replenish sand material

3. High voltage system

3.1 Ultra high voltage host -Supercharger configuration

-Configuration of a single cylinder bidirectional reciprocating plunger supercharger

-Single row two-stage water filtration system (1micron, 0.45micron in series)

-Manual voltage regulation function

-Automatic protection functions such as overpressure shutdown and overtemperature alarm, triple

safety protection

3.2 Special tool kit -Randomly include special tools required for equipment maintenance

3.3 Random accessories

-Main vulnerable parts randomly added

3.4 Cooling system

The use of air-cooled cooling effectively avoids oil water mixing caused by cooler damage caused by

water quality issues, avoids significant losses caused by water ingress into the oil circuit, reduces

failure rates, and better improves cooling efficiency

Main technical parameters of the high-voltage system:

3.2 Special tool kit -Randomly include special tools required for equipment maintenance

3.3 Random accessories

-Main vulnerable parts randomly added

3.4 Cooling system

The use of air-cooled cooling effectively avoids oil water mixing caused by cooler damage caused by

water quality issues, avoids significant losses caused by water ingress into the oil circuit, reduces

failure rates, and better improves cooling efficiency

4. Control system

4.1 Adopting domestic Huaxing advanced control system, integrating large-scale motion control

chips directly into the microcomputer motherboard for higher stability; The host uses a 64G

solid-state storage hard drive, which is faster and has better seismic performance than ordinary

mechanical hard drives; It can be directly imported into DXF drawings for cutting without converting

to NC machining programs.

4.2 The Rhonda 5M controller is connected to the host through the high-speed 485 interface, with the

Baud up to 10Mbps. The servo interface is a bus interface. The network cable is directly connected to

the Weizhi servo driver, reducing the burden of wiring and wiring and reducing the failure point.

4.3 The servo drive system adopts absolute value encoder feedback, and there is no need to return

to the mechanical zero point after power outage or maintenance. The memory battery has a lifespan

of over 3 years. The unique dynamic punching function of the

4.4 system increases the punching efficiency of metal

thick plates by more than 6 times. The

4.5 fast V-shaped AB five axis control mode enables instantaneous interpolation of groove

angles, with significant advantages in trajectory transition processing. Both small rounded corners

and sharp angles can be quickly and smoothly turned, not only ensuring no distortion in the trajectory, but also significantly improving cutting efficiency compared to the right angle five axis.

5. Automatic sand feeding system

Providing sand storage and automatic transfer of sand materials to the sand hopper for water cutting

machines can improve the automation level of the equipment and reduce the labor intensity of

Maximum pressure: 420MPa(60000PSI)

Maximum flow rate: 3.8L/min

System power: 30KW

Power supply: 380VAC, 50Hz , 3-phase 5-wire

operators. -Sand tower capacity 200-300kg

6. Hand operated pulse generator

The manual pulse generator can be carried by the operator to the vicinity of the machine tool to

control the movement of the X, Y, and Z axes. The manual pulse generator is equipped with a

multiplier switch, which can adjust the operating speed in a timely manner, bringing great

convenience to the processing positioning and operation. It will not cause misjudgment of the

processing positioning and the distance between the cutting head and the material due to the

distance between the machine tool console and the machine tool

7. Power system purification

The power input part of the control cabinet is equipped with a three-phase Line filter, and a

high-power three-phase isolation transformer is also added, which purifies the power supply of the

control system and AC servo, and avoids the unstable control factors caused by large interference

from the external power grid

สนใจหรือติดต่อสอบถาม โทร

082-972-9329 (จิมมี่)

083-256-5981 (โกมินทร์)

02-312-0227 (สำนักงาน)

E-mail : [email protected]

salecnc.net

salecnc.net

รีวิว

ยังไม่มีบทวิจารณ์